7 major Factors that Increase Static Friction

written by Stanley Udegbunam || Jan 4th, 2020

AFRILCATE

Have you been wondering what causes static friction to increase?

Then you just bumped into the right website. In today’s article, we will be talking about 9 major factors that increase static friction.

Without further ado, let’s get started.

The 7 factors that increase static friction are:

- High surface irregularity

- A well deformed material

- High intermolecular bond

- Increased surface roughness

- Increased Object weight

- High coefficient of static friction

- High contact surface stickiness

1. High surface Irregularity

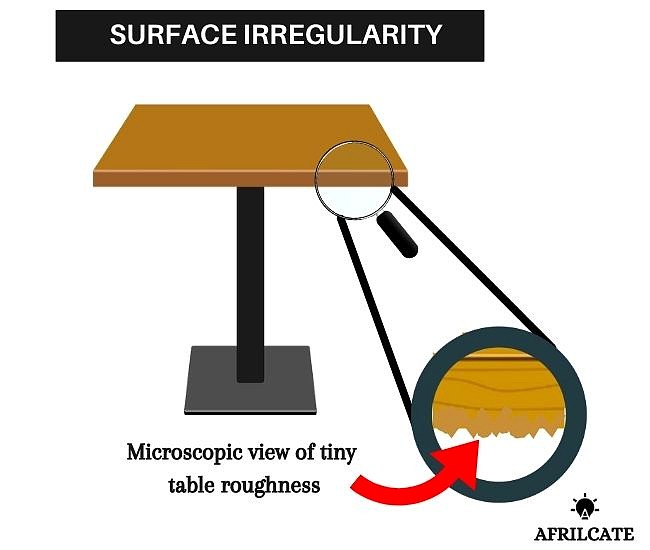

Surface irregularities are tiny rough planes that exists on surfaces.

This tiny surface roughness may not visible to the naked eyes but can easily be detected with microscopic lens.

Let’s see what this surface roughness looks like with a microscope:

Surface irregularity is also called asperity.

If a book is placed on the table, both the asperity of the table and that of the table surface will be interlocked together.

That’s why our article on causes of static friction; clearly states that the interlocking of surface irregularities leads to static friction.

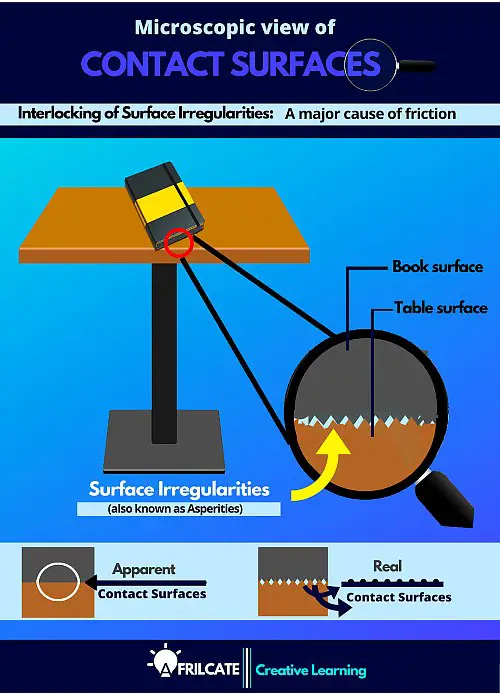

microscopic view of contact surface

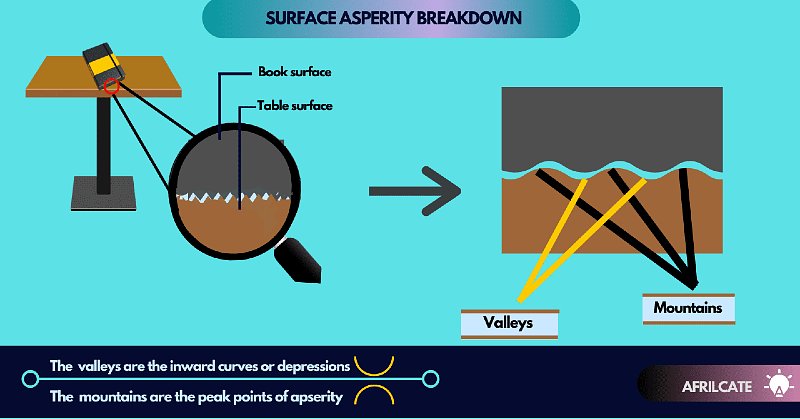

Surface irregularity/asperity consists of surface mountains and valleys.

The mountains of the asperity are the higher points of the irregularity or elevation, while the valleys are the lower points or depressions.

Now the question is: how do high surface irregularities increase static friction?

Surface irregularity is directly proportional to static friction force because the minute surface roughness allows for the interlocking of hills and valleys of asperities.

The greater the unevenness of contact surfaces, the greater the static friction.

Therefore, high surface irregularity will increase the static friction force.

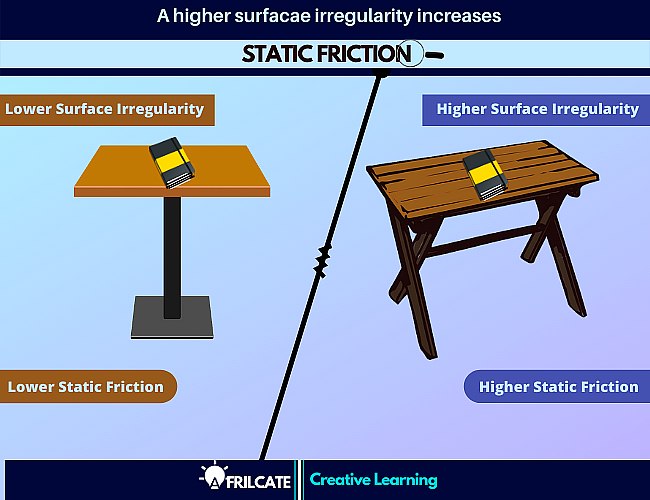

Let’s take the book from the table above and place it on another table with a higher degree of microscopic surface unevenness.

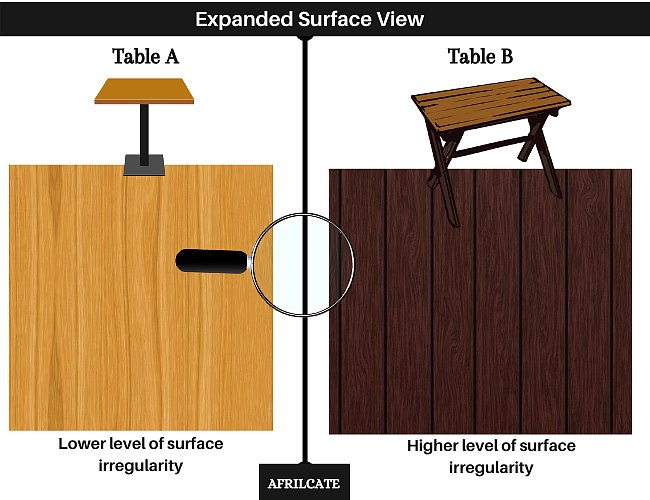

We will call this new table, table B, and the initial one table A.

Comparing both table surfaces:

Since table B have a higher surface irregularity than table A, you should expect the same book placed on surface B to experience a higher static friction.

It’s worth knowing that all objects have microscopic rough planes regardless of how smooth or polished they may appear.

2. A Well Deformed Material

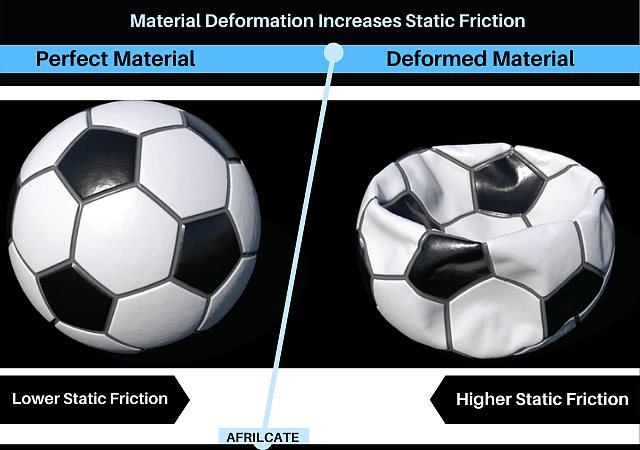

Deformation greatly increases static friction.

The higher the material deformation, the greater the static friction between the contact surfaces.

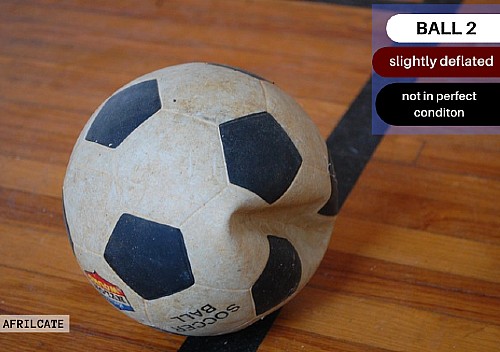

Consider these two soccer balls:

PERFECT CONDITON

SLIGHTLY DEFORMED

Which of these balls will have a greater reluctance to move when tossed into motion with the same applied force and on the same surface?

Ball 1 will have a lower reluctance to motion.

The deformed nature of ball 2 allows for higher contact areas between both surfaces and this creates a high reluctance to motion.

Once the object is set in motion, rolling friction takes over.

Just like static friction, the effect of rolling friction is also more evident in deformed objects.

3. High Intermolecular Bond

Intermolecular bond between contact surfaces leads to surface adhesion.

Surface Adhesion is the force of attraction between molecules of different substances.

When two objects or surfaces are brought into contact, the adhesive or electromagnetic forces attract the molecules of the two objects together.

A common example of surface adhesion is rain droplets on window surfaces just after rainfall or morning dew.

The force of adhesion between the liquid droplets and the glass surface prevents it from sliding down thereby maintaining a stationary position.

These forces of adhesion are weak intermolecular forces popularly known as the van der waal forces.

There are 5 different mechanisms of adhesion, they include:

- Mechanical Adhesion: here, the materials fill the voids or pores of the surfaces and hold surfaces together by interlocking eg sewing

- Chemical Adhesion: Two materials in contact may form a compound at the joint.

- Dispersive Adhesion: the materials are held together by van der waals forces

- Electrostatic Adhesion: A potential difference is formed at the point of contact.

- Diffusive Adhesion: involves the merging of material at the joint by diffusion.

In surface science, the term adhesion almost always refers to dispersive adhesion.

Dispersive adhesion involves the interaction between the molecules of the liquid and the molecules of the solid.

So, whenever we mention adhesion relating to friction force, we are basically talking about dispersive adhesion.

The strength of surface adhesion is largely dependent on:

- the contact angle,

- the shape of the liquid droplet and

- the surface area upon which the two-material contact.

A higher intermolecular bond will lead to a higher adhesive force and a corresponding increase in static friction.

4. Increased Surface Roughness

An increase in surface roughness will lead to higher static friction because rough surfaces hinder motion at the macroscopic level and create more contact points for irregularity interlocking.

This increased con-joined asperity strengthens the adhesive bond which in turn leads to higher static friction.

This is quite similar to the surface irregularity mention above, but a difference exists between both factors.

While surface irregularity refers solely to the joining of materials on the microscopic level, surface roughness refers to surface unevenness at the macroscopic level.

Surface roughness is the type of surface unevenness that we can see with our naked eyes, while surface irregularity is surface unevenness that’s seen only with the help of a magnifying lens.

Nevertheless, the degree of roughness of the contact surface largely affects the extent of coin-joined asperities.

A material placed on rough surfaces has higher static friction than materials placed on smooth surfaces.

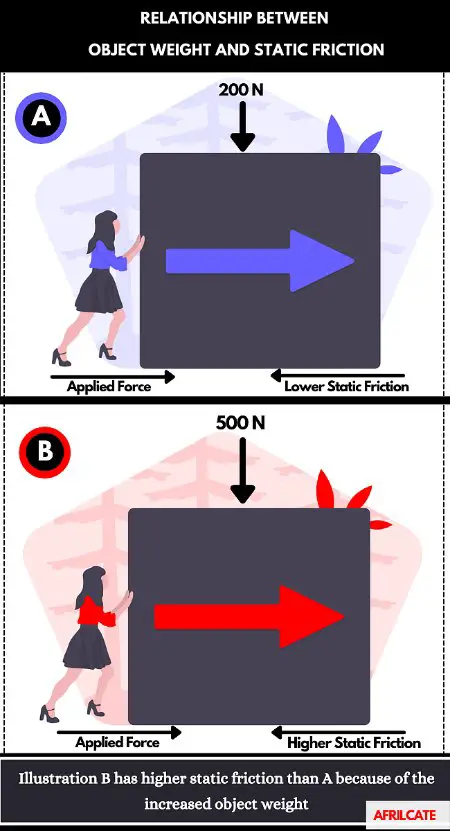

5. Increased Object Weight

The weight of an object is directly proportional to static friction.

Depending on the nature of the material in contact, the object’s weight can affect the degree or extent of the material deformation.

The normal force which is the resisting force acting on the object also depends on the weight of the object.

An increase in object weight will lead to a corresponding increase in static friction.

6. High Contact Surface Stickiness

Surface stickiness increases static friction.

An example of such material is the sticky pad used in automobiles to keep objects intact.

It is placed on car dashboards and it help prevents car accessories from slipping over the surface.

The pad has a large friction coefficient and a multifaced sticky property.

This means it maintains complete stickiness with the dashboard surface and also with the item laid on it.

Pads with a high level of stickiness tend to grip objects firmly.

Another common household example is mouse glue.

The glue board traps moving objects passing across its surface.

Let’s digress a little bit;

Rats in Africa especially in Ghana and Nigeria are getting smarter by the day.

When caught on mouse glue, they quickly urinate on it and struggle to spread it around the contact points to weaken the effect of the glue until they set loose.

As a result of this, the mouse glue is hardly used twice because it’s messed up and rendered ineffective by the 1st rat encounter.

Seldomly, you might encounter some household rat that’s strong enough to even run with the glue board.

As a result of this, mouse glue companies in Africa are continually increasing the efficiency of the trap by using high-level adhesive components strong enough to even trap humans.

A high level of material stickiness increases static friction because the sticky element present in the material has a high adhesive property.

This adhesive property makes the material to be deformed when pressed alongside creating contact entries at the points of application of the force.

The interlocking of both surfaces rapidly increases, static force is increased and a larger resisting force will be needed to break loose.

7. A high Coefficient of Static Friction

The coefficient of static friction is a numerical value that quantifies the degree of stickiness between a static object and its contact surface.

It is the ratio of the Static friction between two contact surfaces to the normal force acting on the body.

The coefficient of static friction is denoted by µs and the formula is:

|

µs = Fs/N |

Where,

- Fs is the static frictional force

- N is the normal force, sometimes it’s denoted by η

This means that the static friction force Fs = N x µs

The means that the static friction is affected by both the normal force and the coefficient of friction.

The coefficient of static friction is increased by either:

- Increasing the normal force acting on the object or

- By increasing the coefficient of static friction

Normal force (N) = Mass (m) x Acceleration due to gravity (g)

Therefore increasing the object weight will increase static friction as discussed earlier.

Coefficient of static friction is a material property.

Increasing the coefficient of static friction entails reviewing the nature of the contact materials and also the surface condition of the surface.

For example:

The static friction coefficient of copper on mild steel on a dry surface is 0.53,

but the static friction coefficient of copper on cast iron is 1.05.

If you wish to increase static friction by increasing the static friction coefficient, you should pay proper attention to the materials under consideration.

Our guide on Static friction coefficient will give you more insight into the coefficient of static friction.

It has a comprehensive friction coefficient table where you get to see the static friction coefficient of different material types and on different surface conditions.

See it here: COEFFICIENT OF STATIC FRICTION

We are gradually coming to the end of this article and you must be wondering why it’s necessary to increase static friction even when it opposes motion right?

Well, the opposition to motion rendered by static friction, can be helpful and needed sometimes.

In automobiles, friction is needed to bring cars to a complete stop when the brake is stepped upon.

The automobile brake manufacturers take these factors discussed above when designing the brake especially the material type in order to have a fast response when depressed.

Unlike popular opinion, the presence of static friction can really be a lifesaver in some case scenario.

Still curious about static friction? see our guide: STATIC FRICTION : The Complete Guide