What are the factors affecting the coefficient of friction?

written by Stanley Udegbunam || March 6th, 2021

There are only two factors that affect the coefficient of friction and they are:

- The nature of the surfaces in contact.

- The friction type (Static, kinetic, or rolling friction)

The coefficient of friction is a surface property. Therefore, its value is constant for a given combination of material surfaces.

The coefficient of friction for given pair of surfaces only varies across different surface conditions like wet, dry, and greasy surfaces.

Nevertheless, these variations are known for different surface pairs through experimental analysis and specified on a friction coefficient table.

How does the nature of contact surfaces affect the coefficient of friction?

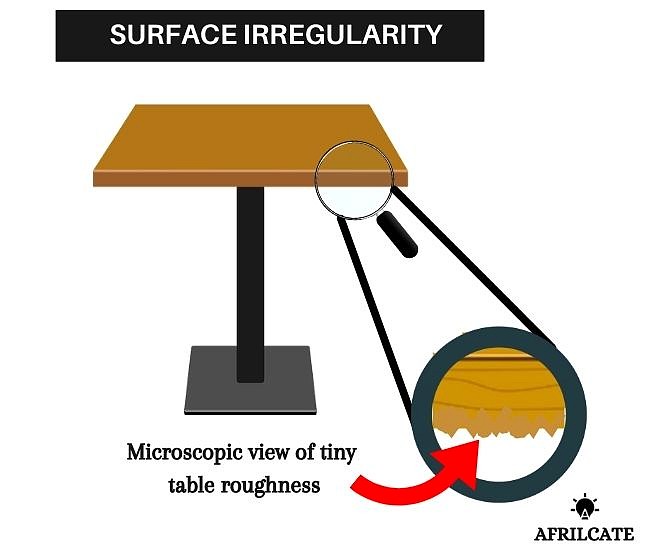

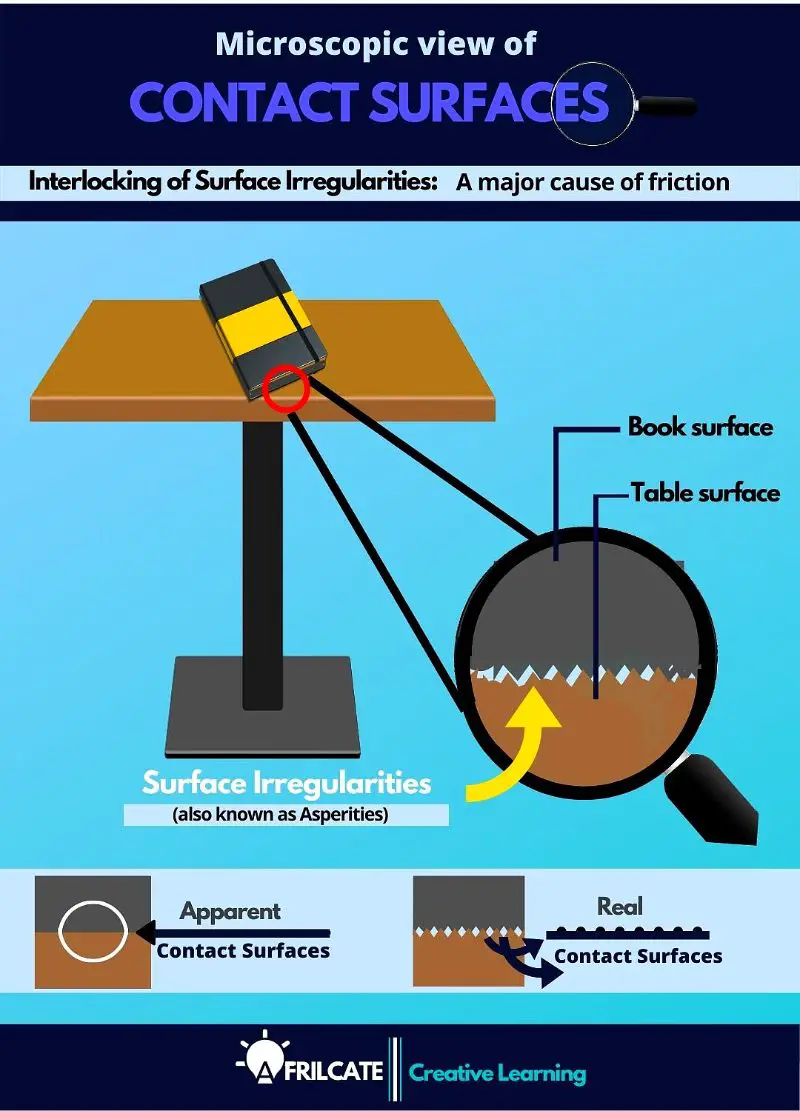

Primarily, friction is caused by the interlocking of tiny surface irregularities known as asperity.

The extent of asperity interlocking varies according to the nature of surfaces in contact.

This means that different surface pairs will either possess a higher or lower friction resistance based on their individual surface property.

As a result of this, the coefficient of friction will be dependent on the nature of contact surface under consideration.

It’s worth knowing that all objects have microscopic rough planes regardless of how smooth or polished they may appear.

NOTE: Coefficient of friction does not exist for a single material but rather for a given pair of surfaces in contact.

Therefore, it’s wrong to say things like: “What’s the coefficient of friction of a rubber chair”

Friction is a contact force, it must involve 2 interacting surfaces, same principle applies to friction coefficients.

Having this in mind, a better question phrase to the format described above will be:

What’s the coefficient of friction of a rubber chair on a concrete floor?

What’s the coefficient of friction of a rubber chair on a rubber tile?

Sounds better now right? (you can just nod in agreement✨).

The answer is provided in the table below.

| MATERIAL COMBINATION | Static Coefficient of Friction (Dry Surface) |

|---|---|

| Rubber on Concrete | 1.0 |

| Rubber on tile | 1.16 |

| MATERIAL COMBINATION | Static Coefficient of Friction (Dry Surface) |

|---|---|

| Rubber on Concrete | 1.0 |

| Rubber on tile | 1.16 |

This table is extracted from Afrilcate’s guide on Static friction coefficient, you can see the complete table here:

Variations of Contact Surfaces with Coefficient of Friction

As mentioned earlier, the coefficient of friction varies across different pairs of surfaces.

Also for a given surface pair, the coefficient changes according to the surface condition.

Surface condition means either wet, dry or greasy surfaces.

Coefficient of friction of Glass on Glass

For Dry surfaces:

the coefficient of friction of glass on glass in a stationary position is 0.94

For Wet surfaces:

the coefficient of friction of glass on glass in a stationary position ranges from 0.1 – 0.6

Coefficient of friction of Leather on Wood

The Coefficient of friction of leather in a stationary position ranges from 0.3 – 0.4

Coefficient of friction of Steel on Steel

For wet surfaces:

The coefficient of friction of steel on steel ranges from 0.09 – 0.19

For dry surfaces:

the coefficient of friction is 0.74

How does the type of friction affect the coefficient of friction?

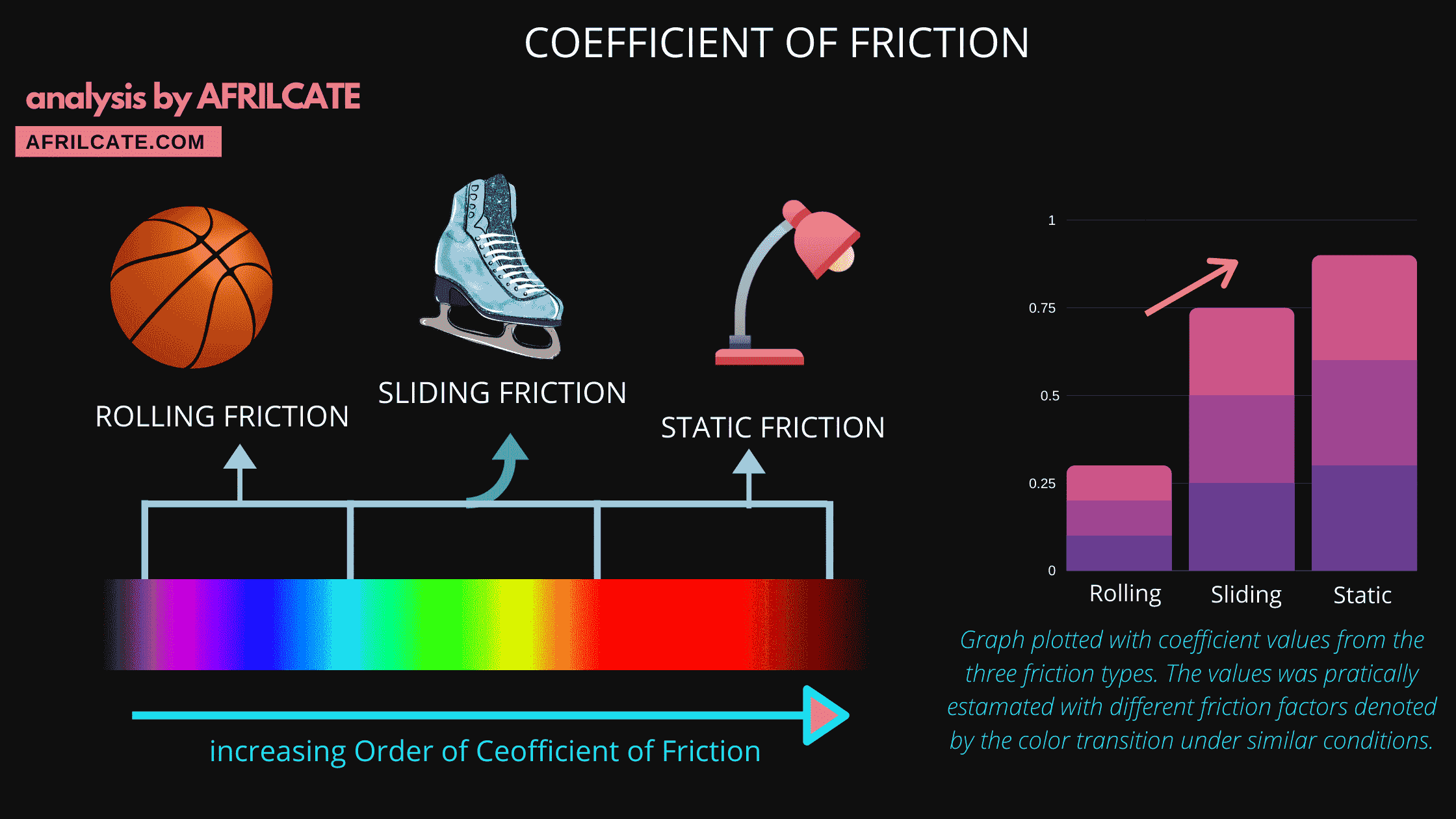

Generally, there are three types of friction:

- Static friction: The friction force between two surfaces at rest relative to each other.

- Kinetic friction: The friction between two surfaces that moves or slides relative to each other.

- Rolling friction: The friction force that resists the rolling motion of an object against a surface. Also known as rolling resistance or rolling drag.

These three friction types possess friction coefficients known as the coefficient of static friction, the coefficient of kinetic friction, and the coefficient of rolling friction respectively where:

Coefficient of static friction: is the numerical value that quantifies the degree of stickiness between a static object and its contact surface.

Coefficient of kinetic friction: is the numerical value that quantifies the friction intensity of a sliding surface relative to another.

Coefficient of rolling friction: is a numerical value that quantifies the degree of motion resistance between a surface and a rolling object.

The static friction coefficient has a higher value when compared to other friction types for a given set of contacting surfaces.

This is because the prolonged/undisturbed state of static position allows more time for asperity locking and molecular bond formation unlike objects in the sliding or rolling state.

That’s why it’s much easier to keep a moving object in motion than to initiate the motion of the object from rest.

Again, the coefficient of rolling friction has the least value when compared to other friction coefficient types for a given set of contacting surfaces.

Variation of friction types with Coefficient of friction

| MATERIAL (dry surfaces) | Coefficient of Static Friction | Coefficient of Kinetic Friction | Coefficient of Rolling Friction |

|---|---|---|---|

| Steel on Steel | 0.74 | 0.57 | 0.001 - 0.002 |

| Rubber on Concrete | 1.0 – 4.0 | 0.6 - 0.85 | 0.35 - 0.45 |

| Rubber on Asphalt | 1.0 – 3.5 | 0.5 - 0.8 | 0.02 |

| Aluminium on Steel | 0.61 | 0.47 | - |

| Copper on Steel | 0.53 | 0.36 | - |

| Wood on Wood | 0.25 – 0.5 | 0.2 | - |

| Glass on Glass | 0.94 | 0.4 | - |

| Teflon on Teflon | 0.04 | 0.04 | - |

| Cast Iron on Cast Iron | 1.1 | 0.15 | - |

| Copper on cast Iron | 1.05 | 0.29 | - |

| Zinc on cast iron | 0.85 | 0.21 | - |

| MATERIAL (dry surfaces) | Coefficient of Static Friction | Coefficient of Kinetic Friction | Coefficient of Rolling Friction |

|---|---|---|---|

| Steel on Steel | 0.74 | 0.57 | 0.001 - 0.002 |

| Rubber on Concrete | 1.0 – 4.0 | 0.6 - 0.85 | 0.35 - 0.45 |

| Rubber on Asphalt | 1.0 – 3.5 | 0.5 - 0.8 | 0.02 |

| Aluminium on Steel | 0.61 | 0.47 | - |

| Copper on Steel | 0.53 | 0.36 | - |

| Wood on Wood | 0.25 – 0.5 | 0.2 | - |

| Glass on Glass | 0.94 | 0.4 | - |

| Teflon on Teflon | 0.04 | 0.04 | - |

| Cast Iron on Cast Iron | 1.1 | 0.15 | - |

| Copper on cast Iron | 1.05 | 0.29 | - |

| Zinc on cast iron | 0.85 | 0.21 | - |

Enjoyed the read?

See other similar friction articles by Afrilcate:

1. What is the direction of static friction?

2. 6 major causes of static friction

3. 7 major Factors that increase static friction

4. 11 Contact Materials with the Highest Coefficient of Friction