6 Major Causes of Static Friction

(with illustrations)

written by Stanley Udegbunam || Jan 4th, 2020

Static friction is the friction force between two surfaces at rest relative to each other.

It is the friction that exists between the contacting surfaces of static objects.

In today’s article, we’ll be looking at the 6 major causes of static friction.

Without further ado, let’s get started.

Static friction is caused by:

- The interlocking of surface irregularities

- Material Deformation of static object.

- Intermolecular bond due to surface adhesion.

- Stickiness of contact surface.

- Surface roughness or degree of smoothness.

- Surface abrasion between contacting pairs.

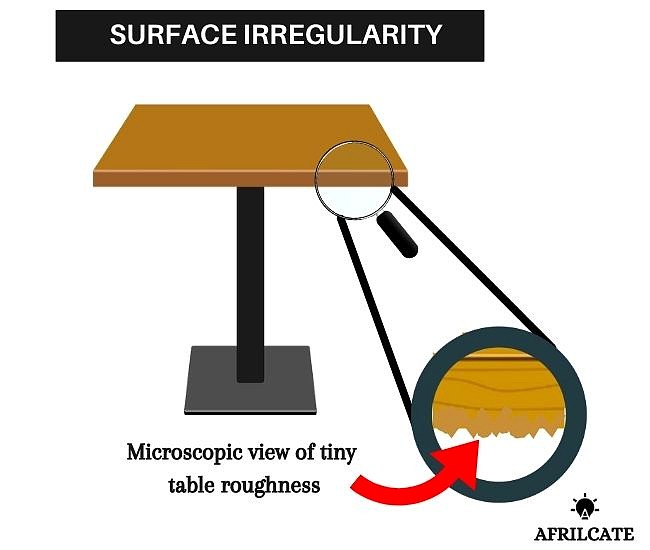

1. INTERLOCKING OF SURFACE IRREGULARITIES

All objects have tiny rough planes regardless of how smooth they may appear.

It might not be visible to the naked eyes but can be detected using microscopic lenses.

These minute rough planes are called surface irregularities.

The interlocking of these surface irregularities give rise to static friction.

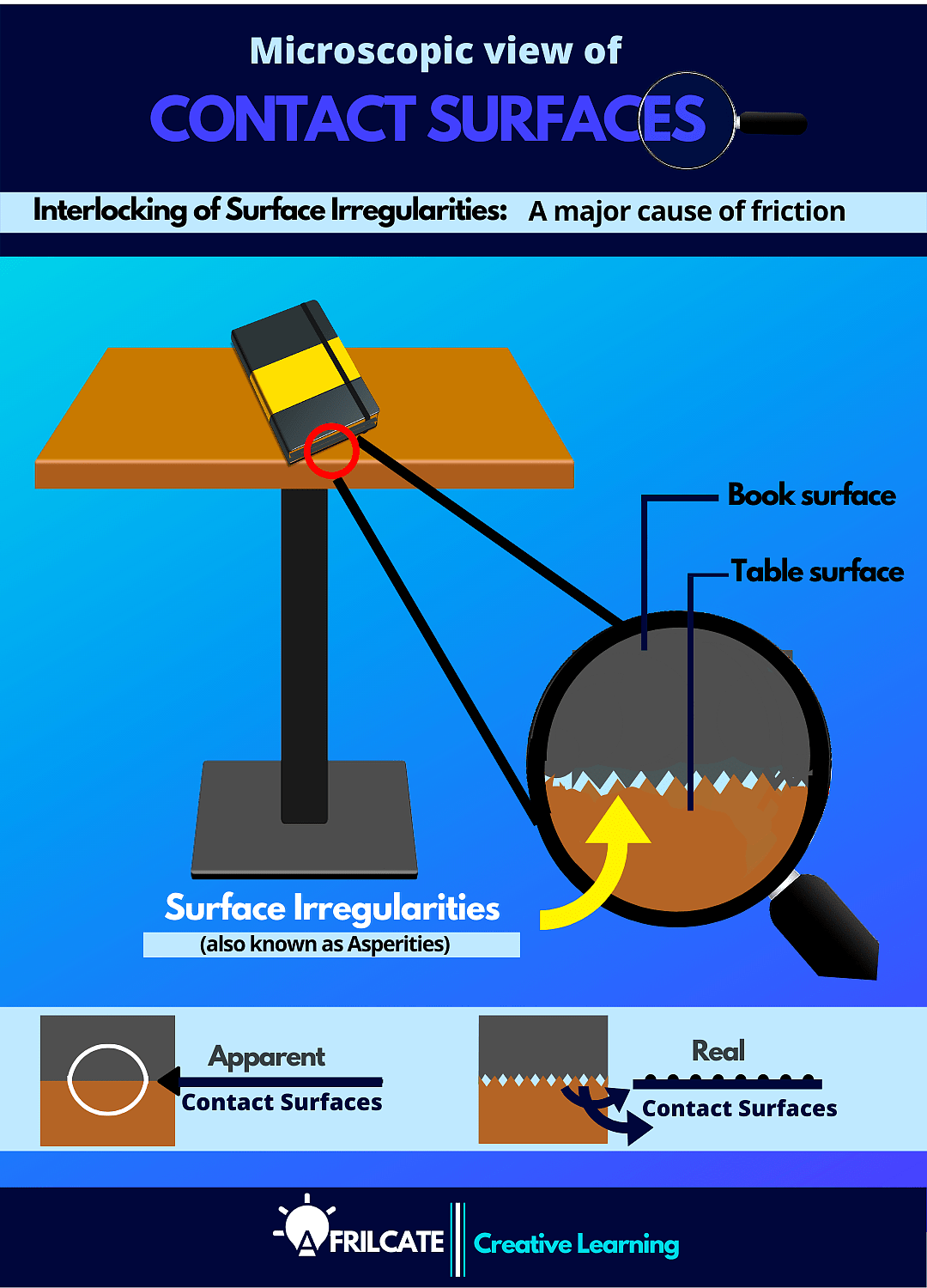

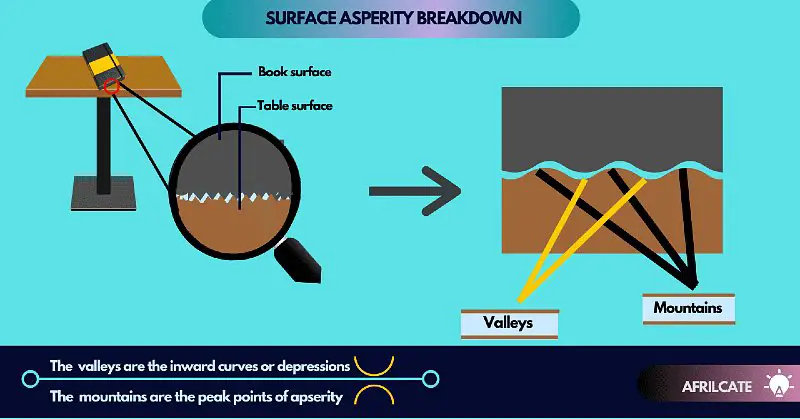

Surface irregularity are also called Asperities; a common term in material science that defines the unevenness of surfaces.

Even if the surface is polished, it still contains tiny bits of unevenness.

Apparently, there is no known material surface that is completely devoid of surface irregularity.

Surface asperity consists of:

- Surface Hills (mountains)

- Surface Valleys (grooves)

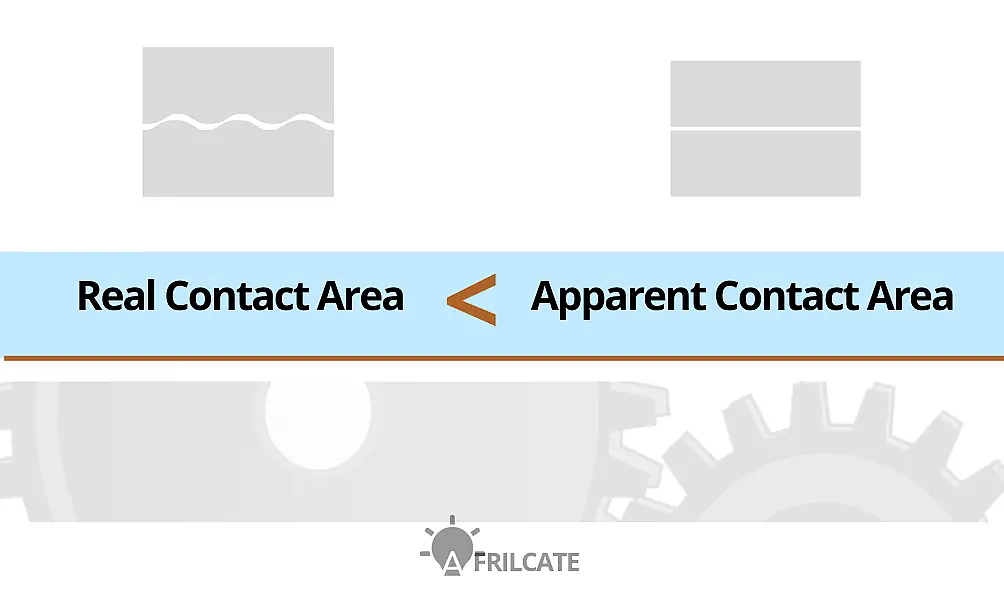

Due to this microscopic surface unevenness, the actual contact area is slightly less than what is expected when viewed with the naked eyes.

Deductive implication;

2. MATERIAL DEFORMATION OF STATIC OBJECT

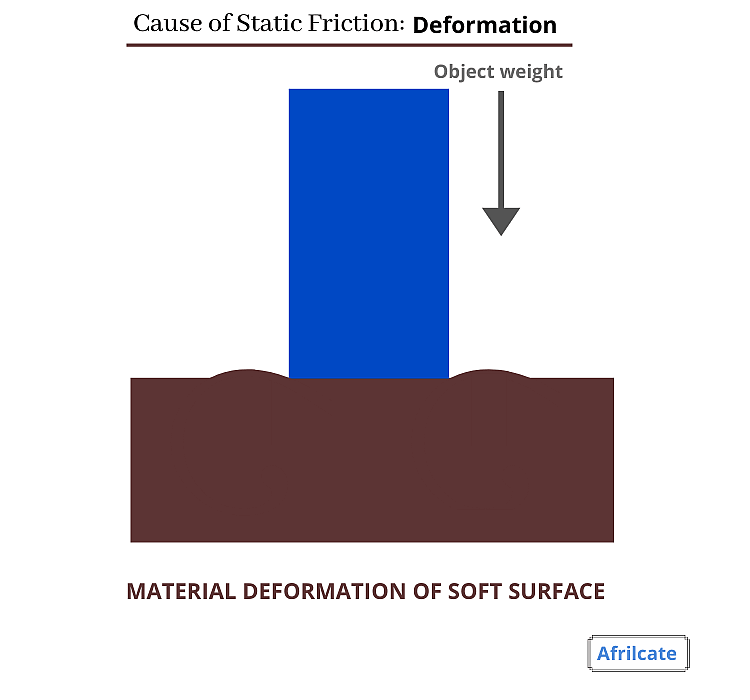

Deformation is another cause of static friction.

The deformation can be elastic or plastic. The force of friction will increase if the two surfaces are pressed harder.

This means an increase in weight will lead to a corresponding increase in static friction.

The weight of an object directly affects the material deformation.

The deformation will continue until the contact area is great enough to support the load.

Excess weight acting on an object can lead to a permanent distortion of the object’s shape or orientation.

This non-reversible deformation is called plastic deformation and large deformation can leads to one object sinking into the other.

Generally, soft material deforms under pressure.

Although such deformations are elastic in nature, it still increases the resistance to motion.

Some common examples of elastic deformation due to friction includes:

- Slight inward depression of our feet when standing on a rug.

- Weight dip when we lie on the bed

- Sitting on an office leathered chair

- Cuddling a pillow

- Rubber tire flattens out at the area of contact with the road.

Want more examples? see this article: 50 + Detailed Examples of Static Friction.

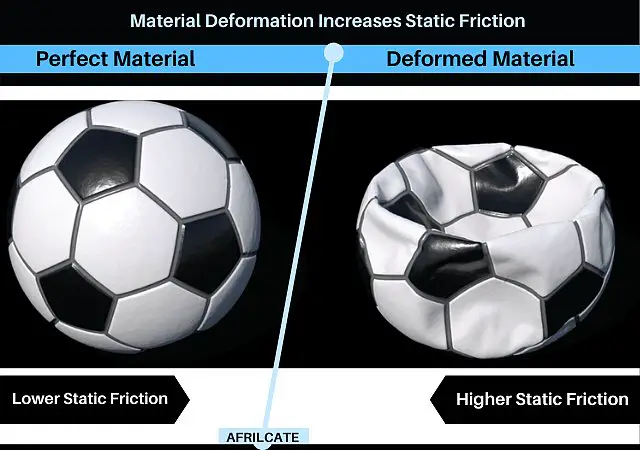

The higher the material deformation, the greater the static friction between the contact surfaces.

3. INTERMOLECULAR BOND DUE TO SURFACE ADHESION

Surface Adhesion is the driving force of static friction.

Adhesion is the force of attraction between molecules of different substances.

When two objects or surfaces are brought into contact, the adhesive or electromagnetic forces attracts the molecules of the two objects together.

A common example of surface adhesion is rain droplets on window surfaces just after rainfall or morning dew.

The force of adhesion between the liquid droplets and the glass surface prevents it from sliding down thereby maintaining a stationary position.

The static nature of the object makes it possible for stronger molecular bonding which in turn leads to a rigid conjoined surface asperity.

In surface science, the term adhesion almost always refers to dispersive adhesion.

Dispersive adhesion involves the interaction between the molecules of the liquid and the molecules of the solid.

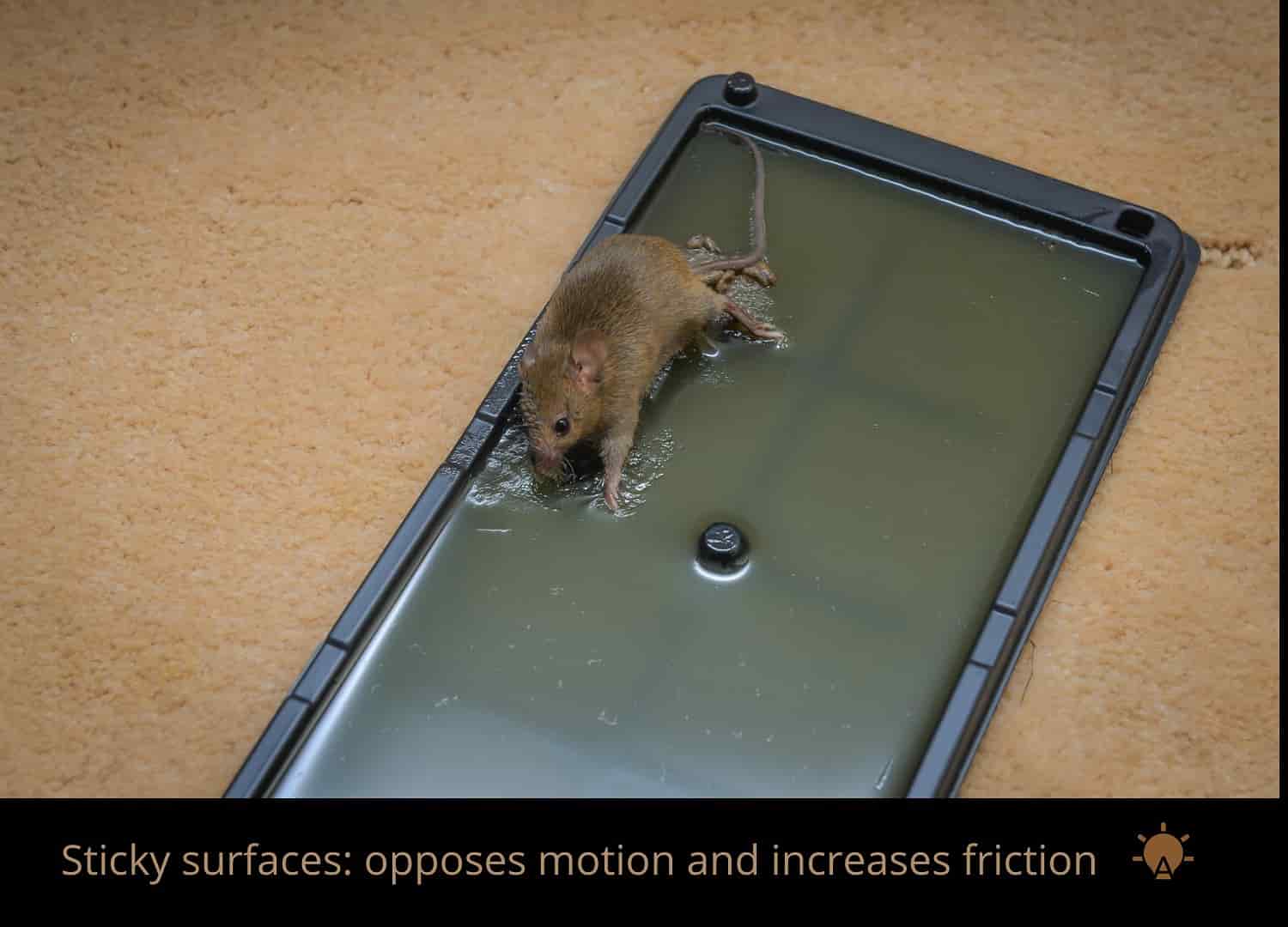

4. STICKINESS OF CONTACT SURFACES

Sticky surfaces also give rise to static friction.

The composition of some solid materials greatly increases their adhesion and makes them even “sticky” to the touch.

For two objects to stick together their surfaces must come in contact as closely, and at as many points, as possible.

This stickiness greatly increases static friction.

Rubber and adhesive tape are examples of sticky materials that have this type of friction.

A common example of sticky surface is the household mouse glue.

Since sticky surfaces enhance static friction, sticky materials like the sticky pad are used in automobiles to keep objects intact.

Another example of sticky material is the sticky pad used in automobiles to keep objects intact.

Sticky pad is a friction device used to prevent objects from sliding on a surface, by effectively increasing the friction between the object and the surface.

It is placed on car dashboards and helps prevents car accessories from slipping over the surface.

The pad has a large friction coefficient and a multifaced sticky property.

This means it maintains complete stickiness with the dashboard surface and also with the item laid on it.

Sticky pads are efficient automobile resources since the acceleration of vehicles can cause objects on dashboards to slip off.

5. DEGREE OF SURFACE ROUGHNESS OR SMOOTHNESS

In many cases, rough surface is referred to as the primary cause of friction.

But this is not always true since adhesion, deformation and other friction causes listed above still have a role to play.

Nevertheless, the degree of the surface roughness greatly affects friction.

An increase in surface roughness will lead to higher static friction because rough surfaces greatly oppose motion in the macroscopic level and creates more contact points for irregularity interlocking.

This increased con-joined asperities, strengthens the adhesive bond which in turn leads to a higher static friction.

If two surfaces in contact are extremely rough, the surface irregularities will be easily locked together.

This is quite similar to surface irregularity mention above, but a difference exists between surface irregularity and surface roughness.

Surface roughness is the type of surface unevenness that we can see with our naked eyes, while surface irregularities is surface unevenness that’s seen only with the help of a magnifying lens.

Nevertheless, the degree of roughness of the contact surface largely affects the extent of coin-joined asperities.

A material placed on smooth surfaces has a lower static friction than materials placed on rough surfaces.

Smoothening rough surface reduces the interlocking of asperities thus causing a decrease in static friction.

The smoother the surface the lower the friction force and vice versa.

To smoothen a rough surface, you can either use sandpaper or apply a coat of high coverage primer.

SURFACE ABRASION BETWEEN CONTACTING PAIR

Abrasion is the process of scraping off or wearing away material surfaces by means of surface contact.

Surface abrasion hinders surface friction by reducing the material roughness.

When surface abrasion occurs, particles of the materials are dislodged from their surfaces. This reduces the chances needed for asperity interlocking and weakens static friction.

When we attempt to move any object, we have to apply a force to overcome interlocking.

For the object to slide over another surface, the adhesive force between the contact molecules must be broken. This process involves the abrasion of contact points.

This means that the interlocked areas must be broken apart or plastically deformed before the object can move.

Once movement is initiated, some abrasion continues to occur, but at a much-reduced level than the static position.

Still curious about static friction? see our guide: STATIC FRICTION : The Complete Guide