11 Contact Materials with Highest Coefficient of Friction

11 Contact Materials with the Highest Coefficient of Friction

written by Stanley Udegbunam || Mar 6th, 2021

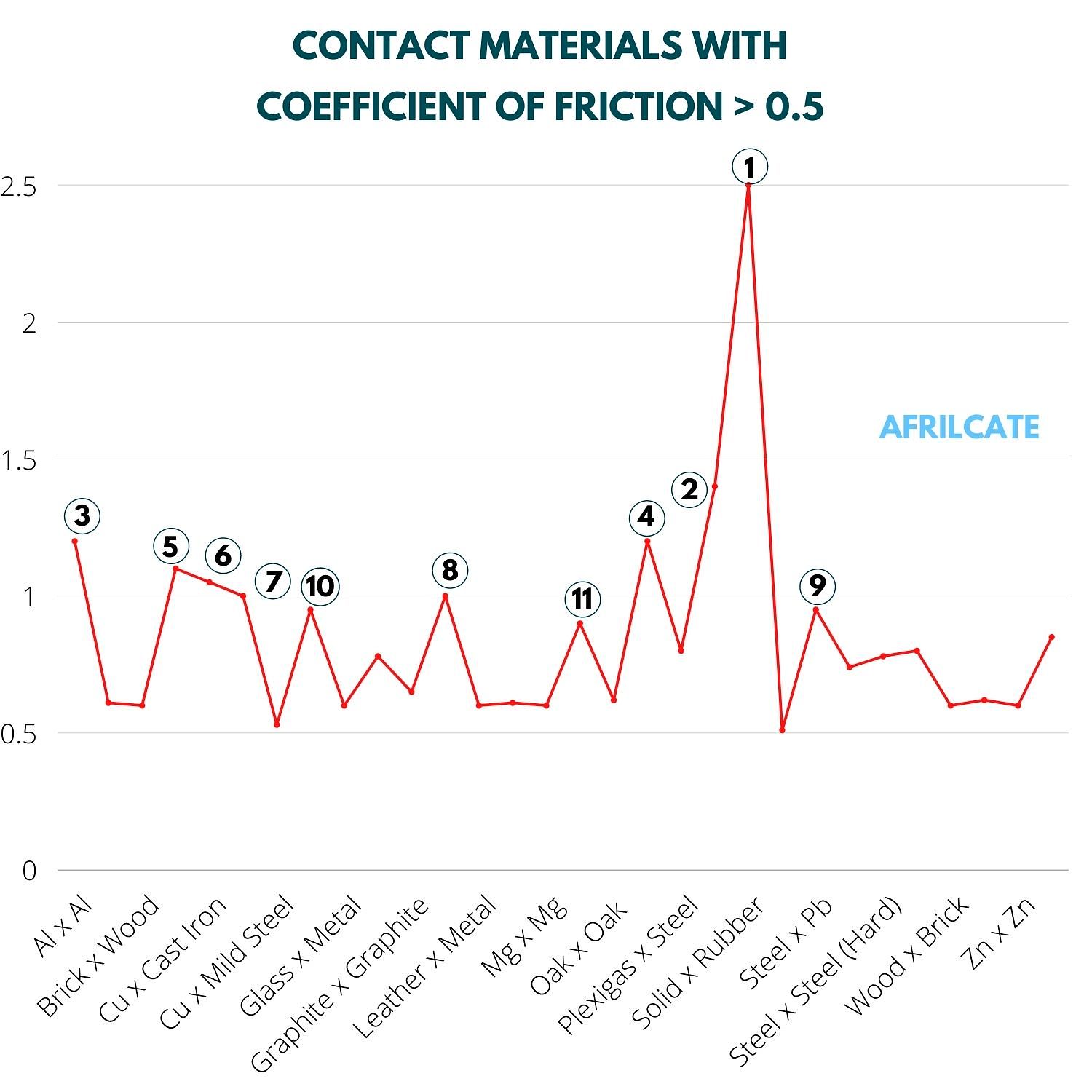

We recently analyzed the coefficient of friction of 91 contact materials currently listed on our friction coefficient table.

And the findings?

We noticed that 30 contact materials have a known coefficient value ≥ 0.5 and 61 contact materials have a coefficient value less than 0.5

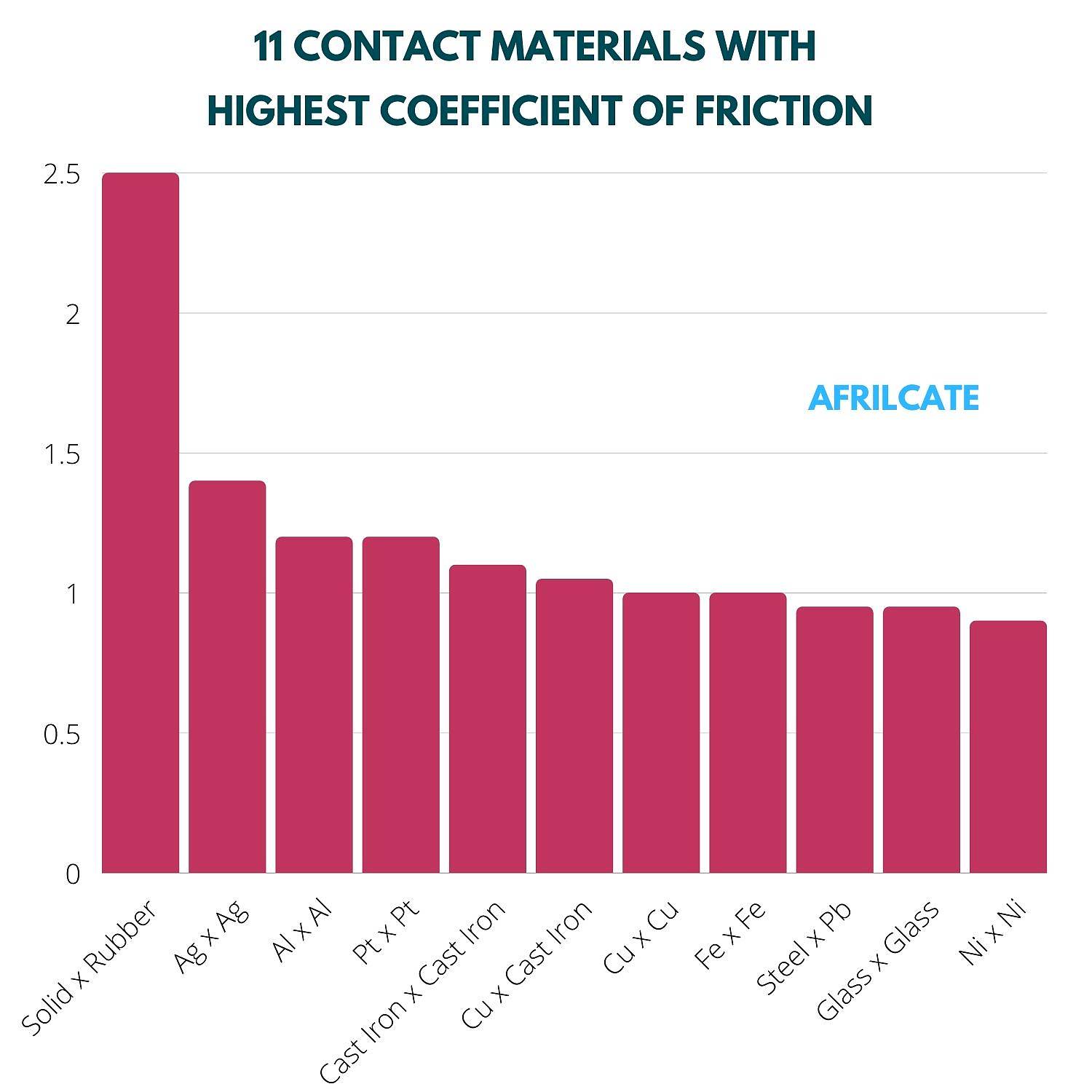

From the analysis, here is a list of the top 11 contact materials with the highest known coefficient of friction.

| No | CONTACT MATERIALS | COEFFICIENT OF FRICTION |

|---|---|---|

| 1. | Solid on Rubber | 1.0 - 4.0 |

| 2. | Silver on Silver | 1.4 |

| 3. | Aluminium on Aluminium | 1.05 - 1.35 |

| 4. | Platinum on Platinum | 1.2 |

| 5. | Cast Iron on Cast Iron | 1.1 |

| 6. | Copper on Cast Iron | 1.05 |

| 7. | Copper on Copper | 1.0 |

| 8. | Iron on Iron | 1.0 |

| 9. | Steel on Lead | 0.95 |

| 10. | Glass on Glass | 0.9 - 1.0 |

| 11 | Nickel on Nickel | 0.7 - 1.1 |

| No | CONTACT MATERIALS | COEFFICIENT OF FRICTION |

|---|---|---|

| 1. | Solid on Rubber | 1.0 - 4.0 |

| 2. | Silver on Silver | 1.4 |

| 3. | Aluminium on Aluminium | 1.05 - 1.35 |

| 4. | Platinum on Platinum | 1.2 |

| 5. | Cast Iron on Cast Iron | 1.1 |

| 6. | Copper on Cast Iron | 1.05 |

| 7. | Copper on Copper | 1.0 |

| 8. | Iron on Iron | 1.0 |

| 9. | Steel on Lead | 0.95 |

| 10. | Glass on Glass | 0.9 - 1.0 |

| 11 | Nickel on Nickel | 0.7 - 1.1 |

NOTE: It’s wrong to say ask questions like “what materials have the highest coefficient of friction?”

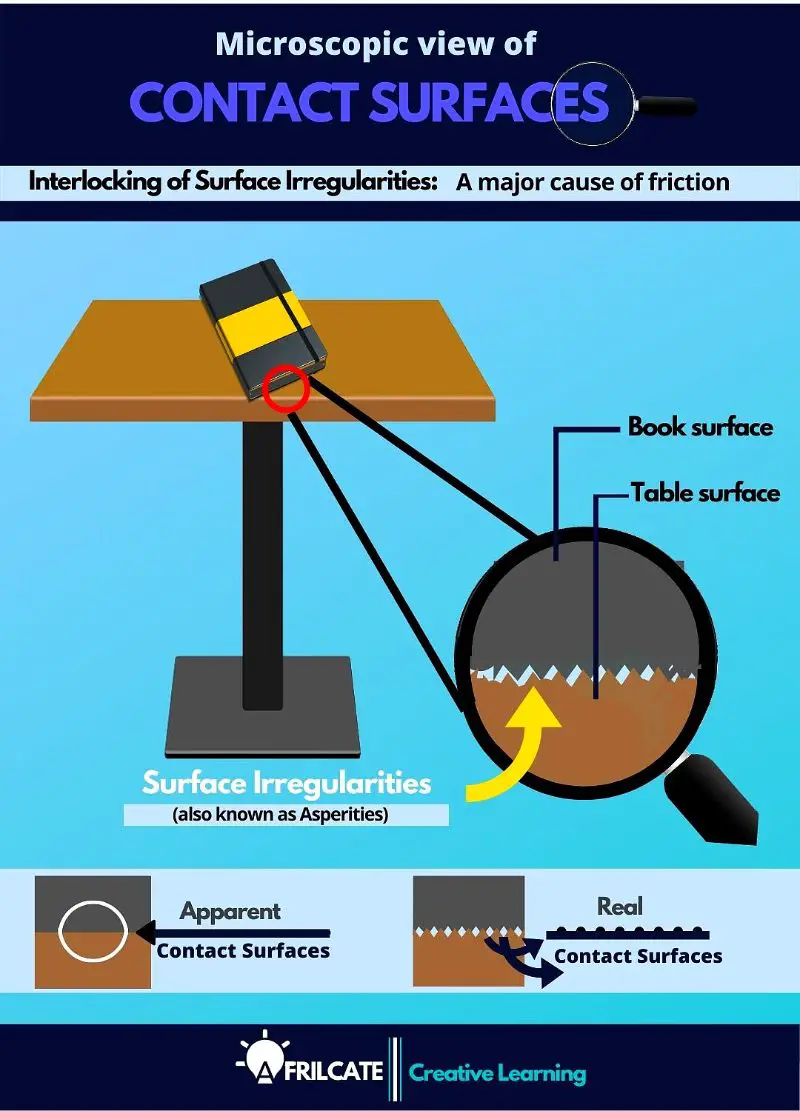

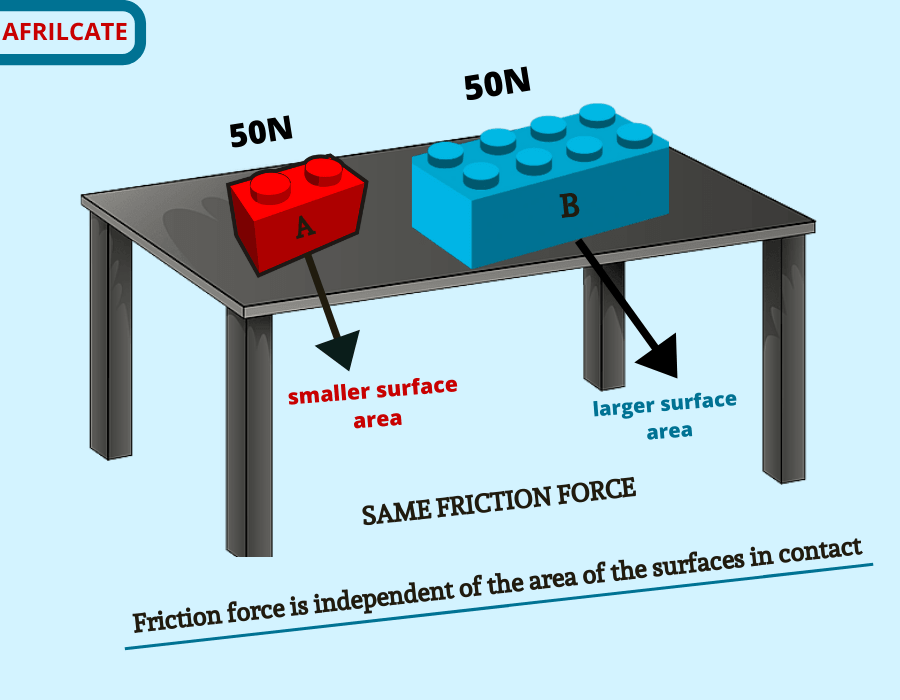

REASONS: Coefficient of friction (C.O.F) is a surface property and not an intrinsic property of individual materials.

This means that coefficient of friction can only exist between two materials in contact.

Let’s simplify this further.

Given 3 materials;

Material A, Material B, and Material C

You can’t talk about the coefficient of friction of Material A as “stand-alone” material.

But rather, the coefficient of friction of Material A on Material B or Material A on Material C.

More like a pair combination and it’s logical since friction itself is a contact force; meaning it must involve two contact surfaces.

Having this in mind, the right question will be:

what contact materials have the highest coefficient of friction? (or paraphrased in any form that signifies material pairs).

And the right answer is clearly outlined in the table above.

Contact Materials with the Highest C.O.F: HOW THE ANALYSIS WAS CARRIED OUT

Few days ago, we published a complete guide on coefficient of friction which contains a friction coefficient table that outlines the C.O.F of over 91 known contact materials.

We needed only materials with high coefficient of friction so we screened the list and selected only materials with coefficient of friction greater than 0.5.

About 30 contact materials fell into this limit.

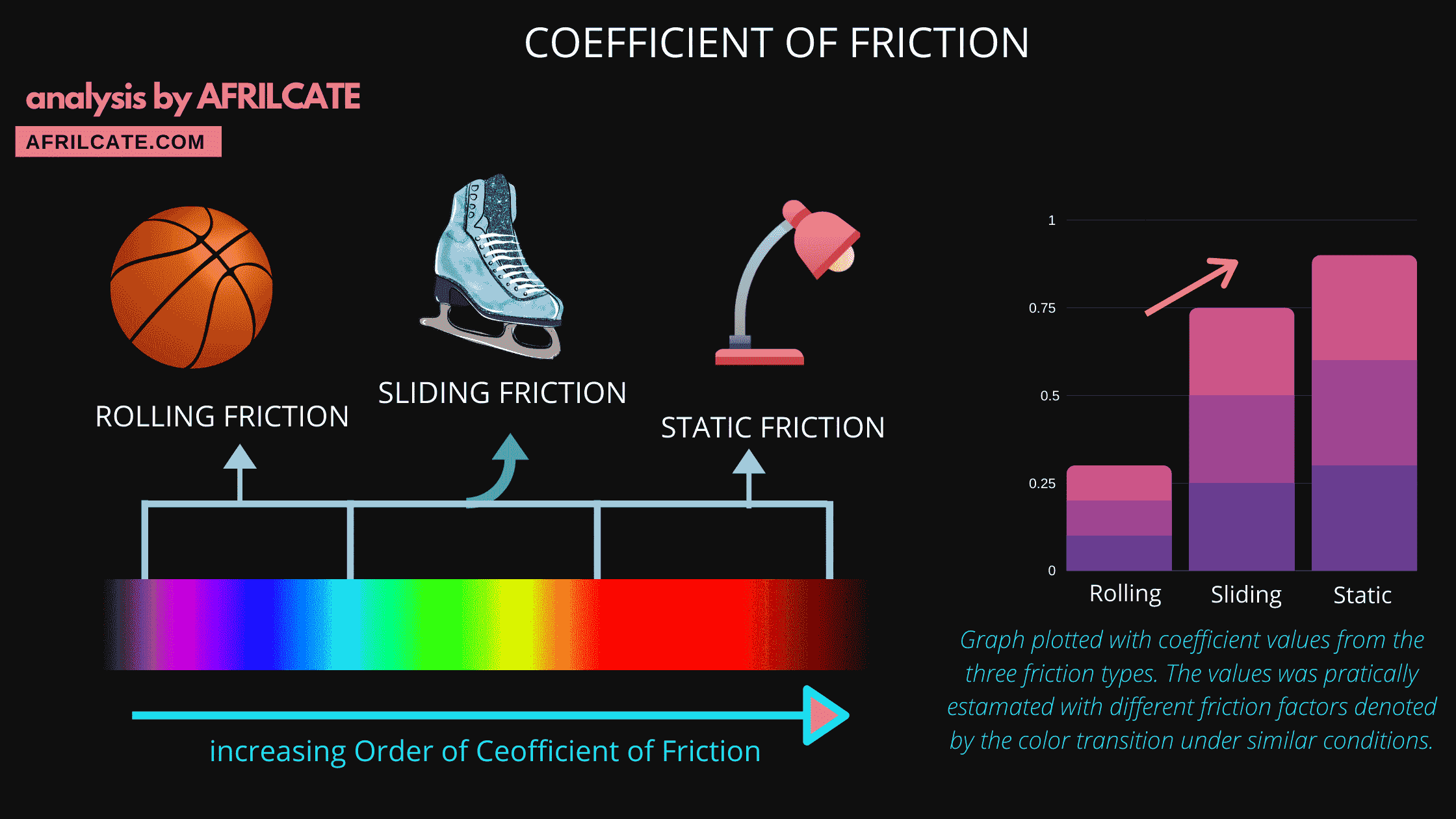

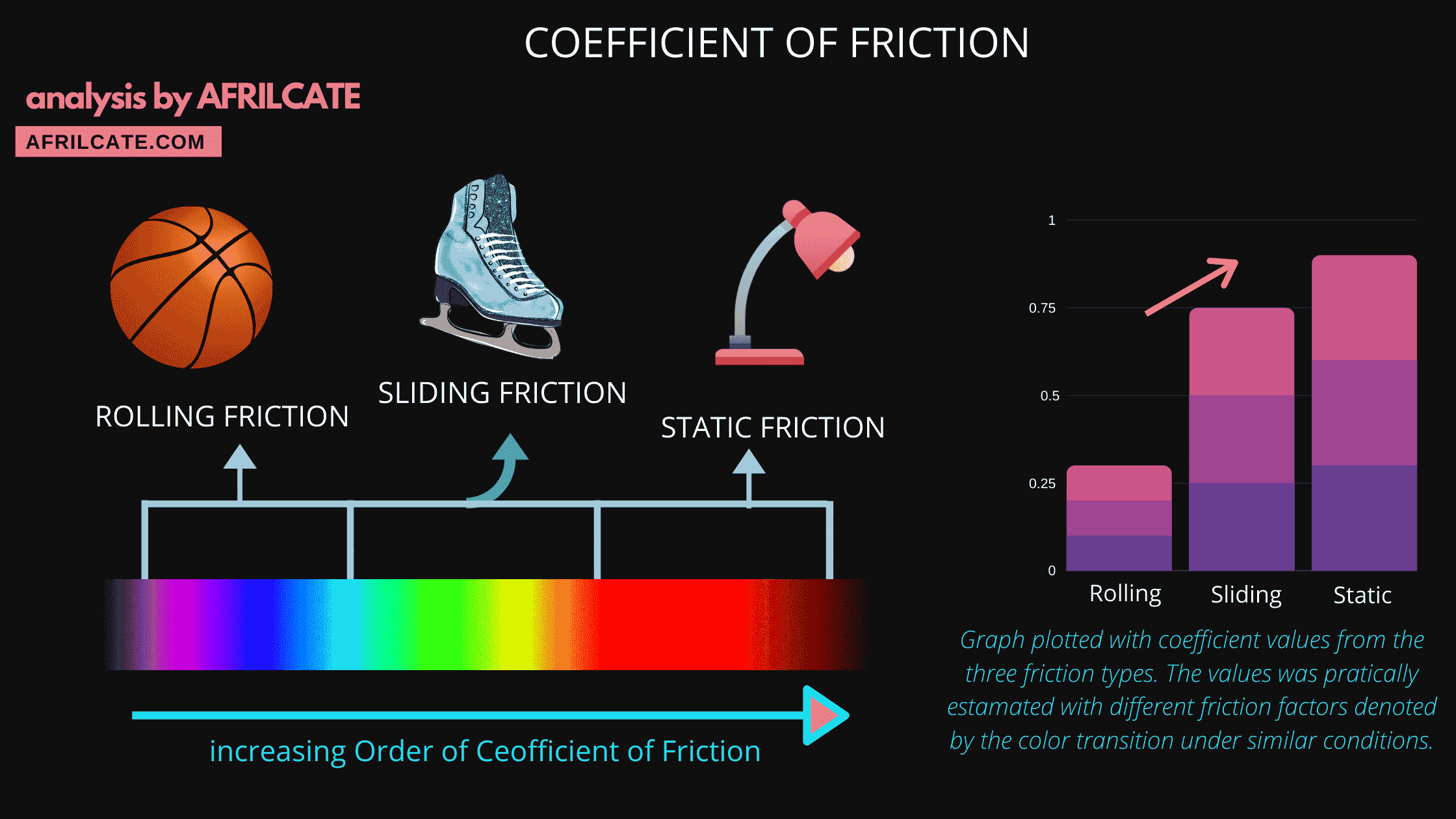

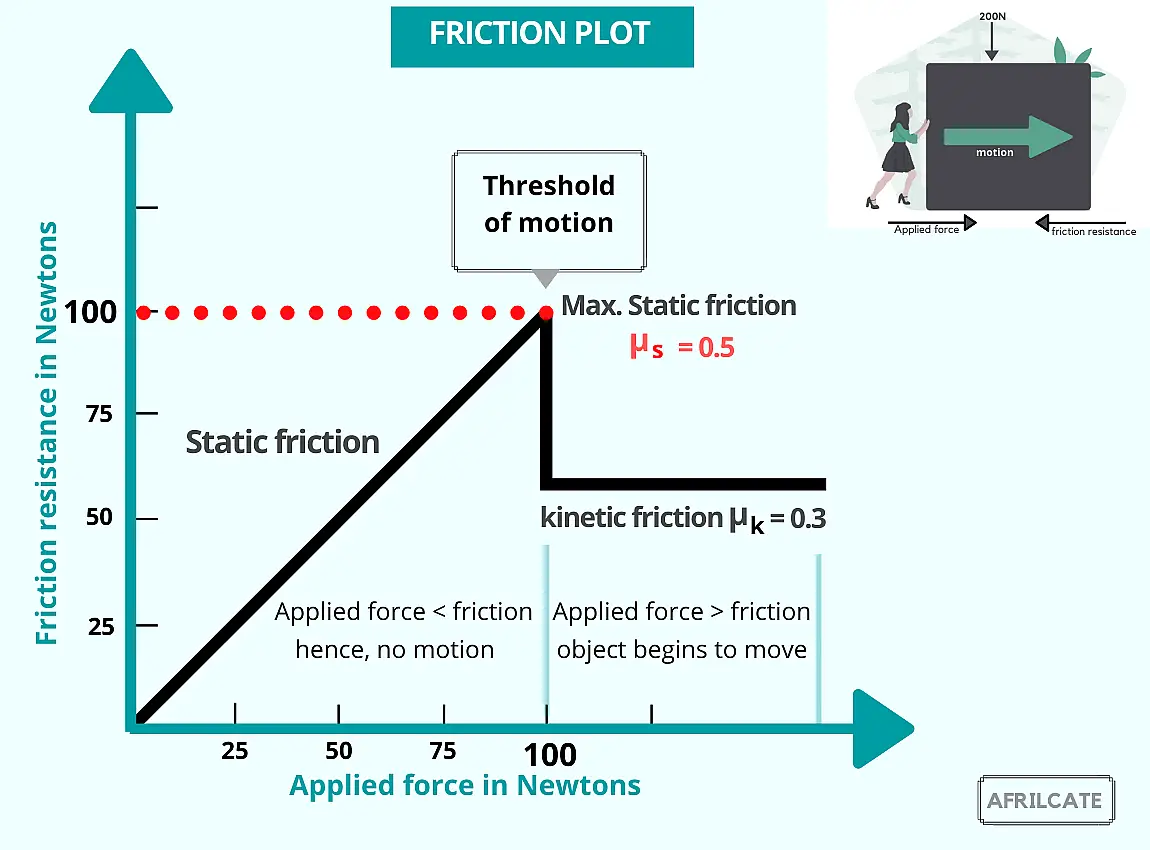

A graph indicating the coefficient of friction on the y-axis and the contact materials on the x-axis was plotted.

Here’s the result:

The graph clearly shows the peak points with the 11 highest coefficient of friction.

Some coefficient values exist in ranges (i.e. x-y).

For the purpose of the plot, the average value was calculated and used on the graph.

For example:

The coefficient of friction of solid on rubber is 1.0 – 4.0

The average coefficient is 2.5. This is a preferred value for graphical purposes only.

The chart below further outlines the 11 contact materials with the highest C.O.F in descending order.

Further Observations:

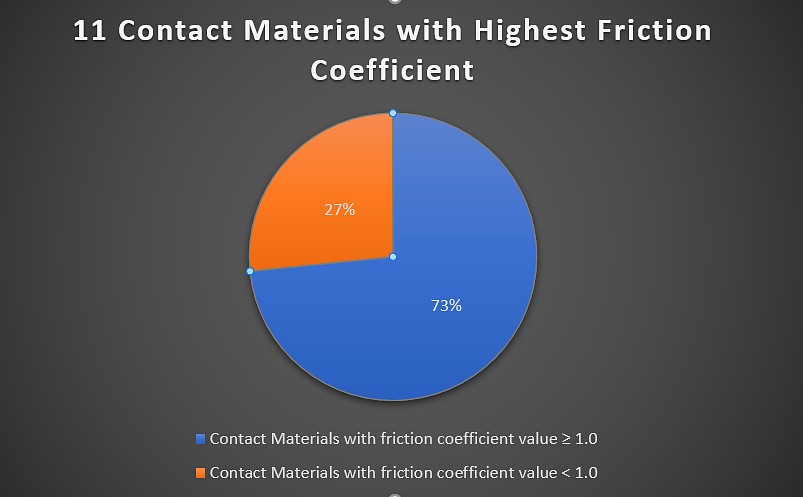

Using the average values, we discovered that 8 of these contact materials have a friction coefficient ≥ 1.0

Contact Materials with friction coefficients equals or greater than 1.0

| No | CONTACT MATERIALS | COEFFICIENT OF FRICTION |

|---|---|---|

| 1. | Solid on Rubber | 1.0 - 4.0 |

| 2. | Silver on Silver | 1.4 |

| 3. | Aluminium on Aluminium | 1.05 - 1.35 |

| 4. | Platinum on Platinum | 1.2 |

| 5. | Cast Iron on Cast Iron | 1.1 |

| 6. | Copper on Cast Iron | 1.05 |

| 7. | Copper on Copper | 1.0 |

| 8. | Iron on Iron | 1.0 |

| No | CONTACT MATERIALS | COEFFICIENT OF FRICTION |

|---|---|---|

| 1. | Solid on Rubber | 1.0 - 4.0 |

| 2. | Silver on Silver | 1.4 |

| 3. | Aluminium on Aluminium | 1.05 - 1.35 |

| 4. | Platinum on Platinum | 1.2 |

| 5. | Cast Iron on Cast Iron | 1.1 |

| 6. | Copper on Cast Iron | 1.05 |

| 7. | Copper on Copper | 1.0 |

| 8. | Iron on Iron | 1.0 |

This accounts for roughly 73% of our list with only 27% falling below coefficient value of 1.0

Contact materials with such high friction coefficient value are required in automobile industries and engineering components to:

- Quickly bring a body to rest

- Avoid motion of specific parts.

QUESTION: What contact materials have the highest coefficient of friction?

ANSWER: Solid on Rubber (1.0 – 4.0)

Enjoyed the read?

See other similar friction articles by Afrilcate:

1. What is the direction of static friction?

2. 6 major causes of static friction

3. 7 major Factors that increase static friction

4. What are the factors affecting the coefficient of friction?

5. Static Friction: The Complete Guide